I worked all morning and then sent the client what I had for review (non-transcription project). I vegged out for a couple of hours since I had nothing else to do until the comments came in and I was bone tired. It was not nice out anyway. I did go out around 1:00 to see if I had mail (no).

Mid-afternoon, it was getting very warm in the RV since I have the dehumidifier running to dry out the under sink area and I was getting antsy, so I decided to go do some work on the sheds.

I started by demolishing the grain chute in the cabin, something I wish I had done last year, since it was very messy! I was surprised by how much bigger the cabin felt after!

After that, I just focused on that half of the cabin, moving things to the shed and garbage pile as needed. I set up a pallet in the corner and stacked storage bins on it, then set up the table between the pallet and the washing machine.

The storage needs for the shed are becoming clear as I start to move ‘stuff’ into it.

The big stuff that has to go in and out needs to be parked at the front by the door, not at the back like this. I need overhead storage for wood.

I really need a proper workbench and, in fact, I found a design for something that I can easily and cheaply build myself. It will go in the corner where the wood is right now. The wall where I set up the board and sawhorses will have a window, so I’m thinking low shelves on the bottom for storing bits and bobs or even a low dresser or cabinet. I’ll keep my eye open at the thrift stores.

Garden tools can fill the north wall (where the wheelbarrow is presently) with hooks or some other system to hang them.

As for the cabin, the east side is a complete disaster, but I’ve carved out a really nice little laundry area on the west side. I haven’t decided yet where I’m putting the dryer, probably on the east side since I don’t use it much.

I screwed a couple of wine crates to the studs for instant storage.

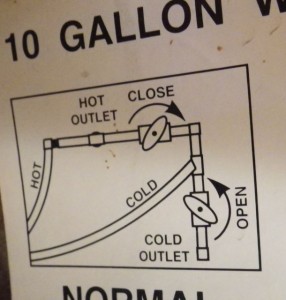

A bucket under the sink will catch water until I find a hose that I could run outside.

I intend for the cabin to be an extension of my home until it is converted into a home. So I want to use it for domestic stuff only, not dirty things. I would really like to get some exercise equipment, especially a treadmill and a bench press, in it. It also needs a light source, but the shed light fixture wouldn’t be enough for this space

While I didn’t care much for living in RV parks, I did miss having other spaces I could retreat to, be they a laundry room, a gym, or a place to spread out a craft project. That’s what I’m getting here at Haven. Some people will scratch their heads and wonder why I don’t get a big house instead. I dunno. I just like this better. 🙂